In a spacious, industrial building, a team of experts works together to assemble a machine meant to operate as a can seamer. Each worker is specifically trained in metal fabrication and other industrial processes, and the machine is passed from one to the other until it is assembled, thoroughly tested, and ready to head out the door to a factory assembly line.

It is a rare sight in this age of automation, but it’s just another day at the office for the team at Peekskill’s Bantam Tools.

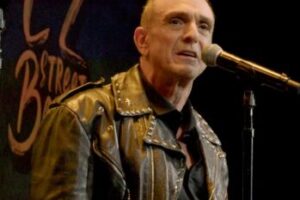

Owned by educator, entrepreneur, and tech expert Bre Pettis, Bantam’s 15,000 square foot waterfront facility spans four buildings and produces CNC (Computer Numerical Control) milling machines.

“I think when people think about factories, they think of some dismal place of repetitive tasks – not a very inspiring image,” says Pettis. “But here at Bantam Tools, we’ve got this awesome team of really smart people who take pride in their work, and that’s the way it has to be.”

The machines are similar to 3D printers except instead of building items layer by layer, a CNC milling machine takes a block of metal provided by a metal distributor and cuts away the excess to create an item such as a tool or a mechanical component.

***

3D printing is a familiar world to Pettis, who began as a Seattle schoolteacher making video blogs (before the advent of YouTube) and went on to become an integral part of the 3D printing revolution as co-founder of MakerBot in 2009. He bought Bantam Tools in 2017 and moved its facilities to Peekskill in 2019.

“When it was time to find a new place for Bantam Tools, it was really clear – Peekskill’s the place to be,” says Pettis. “It’s a combination of a beautiful natural environment with a diverse, smart community.”

As a part of the Peekskill community, Bantam Tools has worked closely with the high school’s robotics team, as well as offered several grants to local artists.

***

Pettis is proud to be part of a movement encouraging manufacturing and industry in America, since his tools, which may be similar to those panel benders, are used by what he calls the “skill-builders and world changers” who are putting their products out into the world. He also feels that this is the perfect time for such a movement.

“We’re in an interesting moment right now, because we’ve gotten really accustomed to things being made elsewhere and being brought here, and being able to buy it super affordably at the cost of low wages somewhere else,” says Pettis. “And with the trade wars, tariffs, the supply chain disaster … we have a good opportunity to reengage with our connection to the things we use and buy.”

According to Pettis, one of the biggest obstacles to a manufacturing resurgence is a cultural one. As a child, things like factory tours and shop class excited and inspired him. Now those factories are closed down, and very few schools still offer shop classes. Somewhere along the way, Pettis says, children were told that manufacturing and trades were for people who couldn’t handle higher education.

“In reality, the kind of things you learn in wood shop and metal shop and auto shop – that’s the kind of stuff they teach at MIT,” he says.

***

Scan this code to hear Christian’s full interview with Bre Pettis on RiverTalk.

One of Bantam Tools’ goals is an educational one – providing people with the tools they need to understand and use the technology.

One of Bantam Tools’ goals is an educational one – providing people with the tools they need to understand and use the technology.

“When people get involved, there is definitely a learning curve,” says Pettis. “Our frontier is to help people get up that mountain and get that good view from the top as a machinist making parts for whatever they need.”

Pettis hopes to use his enthusiasm and the products of Bantam Tools to help fuel a new wave of American manufacturing and share the joy of creating.

“If we can tell more stories about manufacturing and open the window to folks so they can understand the satisfaction, the delight, the awesome chemicals that get released in your brain when you fix something or manufacture something, and see something you’ve made, I think that’s the most important thing for changing our culture and embracing manufacturing in America.”

Christian Larson, who lives in Peekskill, is Editor-at-Large of River Journal North, and host of its podcast RiverTalk. He is also an event planner. Visit capngoodtimes.com/