A subway system runs 24/7 through coordinated staffing, real-time monitoring, and constant maintenance. Specialized teams clean, repair, and operate trains across all hours. Behind every smooth ride is a layer of nonstop planning.

Most commuters rarely think about the effort that goes into the trains they board. But running a subway system every minute of every day requires deep coordination between people, machines, and systems. This article explores what it really takes to keep the underground moving while the city sleeps.

Behind-the-Scenes Workforce: The Human Engine

A 24/7 subway depends on its people. Train operators, dispatchers, mechanics, station agents, electricians, and cleaners form the core of the operation. Each role is critical to safety, reliability, and performance.

Shift scheduling must be precise. Managers rotate teams to ensure full coverage across peak hours, nights, and weekends. Fatigue, absenteeism, and emergencies require built-in flexibility and redundancy.

To strengthen workforce operations:

- Stagger shifts to maintain coverage without burnout.

- Cross-train staff to cover multiple roles during disruptions.

- Maintain fast, clear communication between field staff and central control.

Without this human engine, even the most advanced systems fall short.

Maintenance Without Stopping the Clock

Subways don’t have the luxury of long downtime. Tracks, trains, signals, and stations require constant attention, even while service is ongoing. Maintenance crews must operate within tight windows and live environments.

Key strategies include:

- Nighttime track access: Maintenance is scheduled during off-peak hours when fewer trains are running.

- Mobile response teams: Specialized units perform fast diagnostics and on-the-go repairs.

- Predictive maintenance: Sensors detect wear early so teams can act before failures occur.

These practices help reduce system-wide disruptions and extend the life of critical infrastructure. Maintenance never stops; it just adapts to the rhythm of the city.

Powering a City: Energy, Signals, and Systems

Reliable electricity powers every part of the subway system, from train movement to station lighting. Most systems rely on a third rail subway design, where electric current flows through a high-voltage rail running alongside the tracks. Backup systems are crucial to keep the network stable during power interruptions.

Signal systems are equally essential. They govern train spacing, routing, and speed, ensuring safe movement across complex track layouts. Control centers monitor signal health in real time and intervene when irregularities arise.

To keep these systems strong:

- Conduct routine inspections of power substations and third-rail components.

- Use smart monitoring to flag voltage or signal fluctuations.

- Train response teams to troubleshoot failures quickly and safely.

Power and signaling are the heartbeat of continuous service. Without them, the system stops cold.

Keeping It Clean and Safe, Round the Clock

Cleanliness and safety aren’t cosmetic; they’re operational priorities. Subway stations see thousands of riders per hour, and without constant care, conditions can quickly decline. A safe, clean system builds public trust and supports ridership.

Core strategies include:

- Rotating cleaning crews to sanitize high-touch surfaces and remove waste multiple times a day.

- Round-the-clock security patrols with real-time camera feeds and emergency response systems.

- Rapid response teams handle spills, equipment hazards, and urgent safety issues.

Maintaining safety and cleanliness is a daily battle, but one that keeps the system usable and welcoming for everyone.

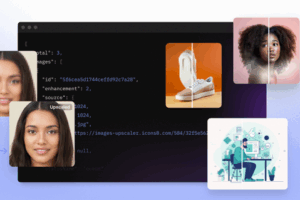

Tech and Data: The Silent Backbone

Technology ties everything together behind the scenes. Sensors monitor rail temperature, signal health, and equipment vibration. Central systems use this data to alert teams before issues turn into outages.

Data also helps with planning. It tracks crowd flow, train delays, and maintenance trends. This enables smarter scheduling and better resource allocation.

Dashboards in control centers give operators a live view of the system. Staff can adjust train frequency, reroute traffic, or communicate with riders instantly. Without this digital backbone, modern subway operations would grind to a halt.

Conclusion

Running a subway system 24/7 takes more than just running trains. It demands seamless coordination between human labor, mechanical systems, and digital tools.

From the third rail to control rooms, every element must work in sync. When it all comes together, riders experience a service that feels effortless, even though it never sleeps.